1. Frame Materials

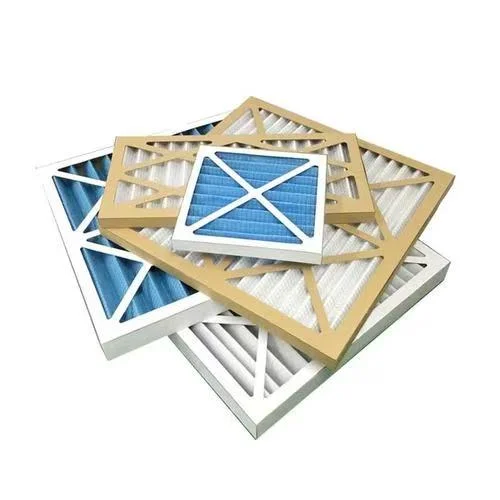

Primary cardboard filters typically utilize four frame material types:

- Paper frame (most economical, widely used)

- Aluminum frame

- Galvanized steel frame

- Stainless steel frame

Paper frame filters are cost-effective solutions primarily installed in:

- Air handling units (AHUs)

- HVAC systems

- Fresh air intakes

- Dust collection system inlets

2. Filtration Efficiency Grades

Paper frame filters are classified into four efficiency levels (EN779 standard):

| Grade | Particle Size | Efficiency |

|-------|--------------|------------|

| G1 | 5μm | 40% |

| G2 | 5μm | 65% |

| G3 | 5μm | 85% |

| G4 | 5μm | 90% |

3. Structural Features

- High air permeability with low airflow resistance (energy efficient operation)

- Dense non-woven filter media achieving >90% efficiency for 5μm particles

- Reinforced construction:

- Standard paper frame (handcrafted for small batches, die-stamped for mass production)

- Optional metal frames (galvanized/Al/stainless steel)

- High dust-holding capacity for extended service life

Innovative Design Improvement:

The upgraded version eliminates traditional metal skeletons, instead using filter media with integrated wire mesh supports. This modification:

✓ Simplifies manufacturing processes

✓ Reduces production costs

✓ Maintains equivalent performance

4. Standard Thickness Options

Available in multiple depths: 15mm, 21mm, 25mm, 46mm, 50mm, 80mm, 96mm

5. Applications

Designed for commercial/industrial HVAC systems and cleanroom ventilation pre-filtration:

- Civil buildings: Offices, hospitals, malls, airports, stadiums

- Industrial facilities: Factory ventilation systems

- Critical environments: Cleanroom air handling systems

Note: All specifications comply with international air filtration standards.

https://www.amdfil.com/primary-filter-frames-and-paper-frame-filter-specifications.html